Example 1

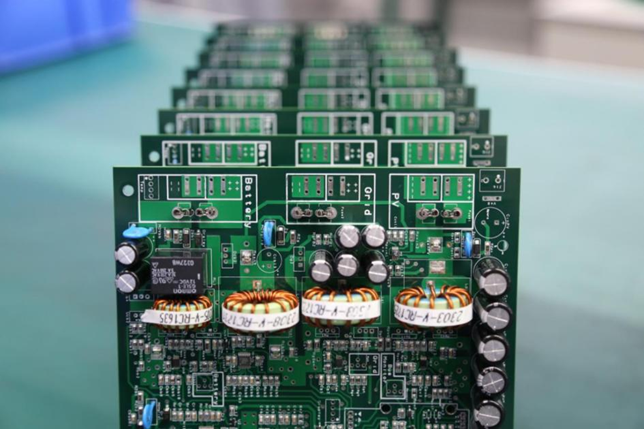

Facing a Dilemma: Upgrading 50 PCBs with Problematic GSM Modules

Imagine having 50 PCBs with troublesome surface mount GSM modules that desperately needed reprogramming. The catch? These modules couldn't be accessed directly from an external PC for the manufacturer's upgrade utility. To make matters worse, the main CPU linked to the GSM module lacked the memory required to store the new firmware.

Enter Envision Remote!

Following the manufacturer's guidance on utilizing AT commands for firmware reprogramming, our customer crafted a clever C script. This script took charge, halting the main CPU, assuming control of the UART, and sending the necessary AT commands to execute the upgrade. What's more, it could read the firmware image from the PC's local drive and send it in manageable blocks to the GSM module, eliminating any size limitations. Each PCB was upgraded in just a matter of minutes.

The alternative would have been a costly, labor-intensive process of physically replacing the modules. With Envision Remote, it was as simple as running a C script!

Example 2

When Field Testing Meets Real-World Challenges

Imagine conducting a field trial for a new battery-powered data collector, right in the heart of a field. This product, designed for practical applications, posed unique challenges that couldn't be fully addressed in the confines of an office-based R&D environment. The collector lacked built-in communication capabilities, such as GSM or Wi-Fi, making real-time data capture seem like an uphill battle. But, as always, Envision Remote stepped in to save the day!

We provided our customer with a versatile toolkit, including a dual-port power bank, a compact 4G-to-Ethernet router, and a 4G USB modem with a SIM card. The power bank powered both the router and Envision Remote, while the 4G modem seamlessly integrated with the router. Once the 4G connection was established, Envision Remote swiftly communicated with the server, identified the target device, and commenced real-time data recording.

Our customer conducted a series of tests, meticulously noting the timing of each. The logged data captured intricate details detected by the product. By aligning the log timestamps with their test records, our customer effortlessly accessed and scrutinized the data from each test.

What's even more remarkable, our team of engineers back in the office could remotely identify areas for improvement and swiftly reprogram the product. This allowed for rapid adjustments, retesting, and saved everyone from multiple field trips. Envision Remote: Streamlining Field Trials with Precision!